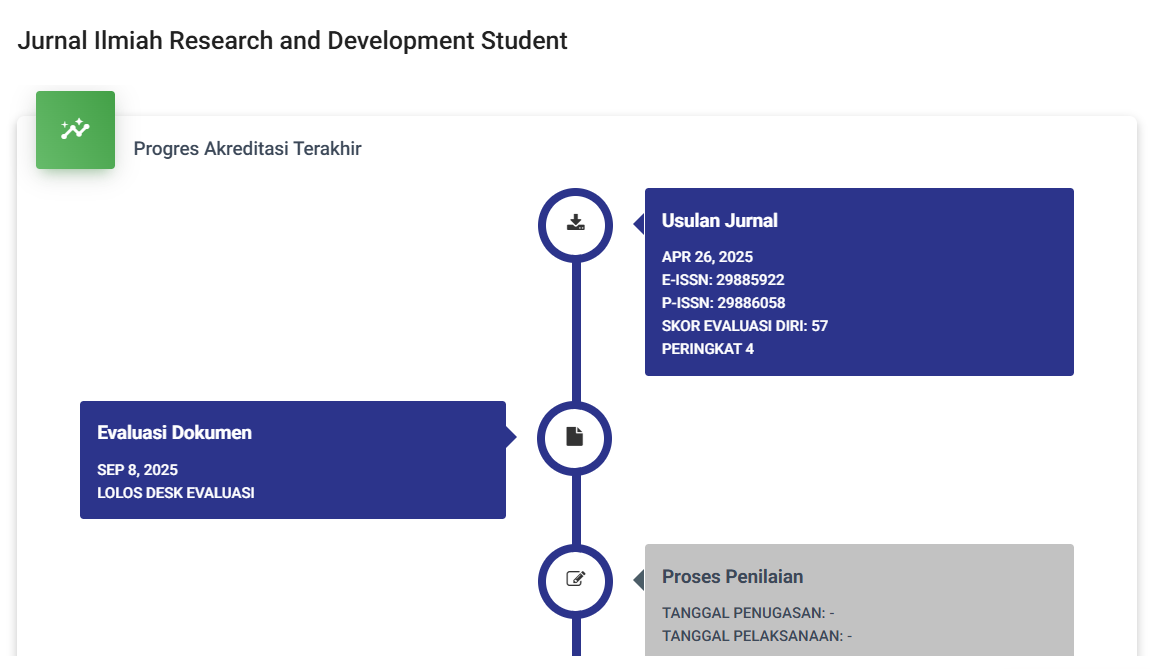

TOTAL PRODUCTIVE MAINTENANCE (TPM) PADA PERAWATAN MESIN JAHIT MENGGUNAKAN OVERALL EQUIPMENT EFFECTIVENESS (OEE) DI CV. CAHAYA SETIA MULIA

DOI:

https://doi.org/10.59024/jis.v3i1.1053Keywords:

kegagalan, pengendalian, produksi.Abstract

Penelitian ini bertujuan untuk menganalisis system perawatan pada mesin produksi yang digunakan oleh CV. Cahaya Setia Mulia dan menganalisis faktor-faktor yang mempengaruhi tinggi rendahnya nilai OEE pada mesin jahit dengan focus melakukan perencanaan Total Productive Maintenance yang didukung oleh pendekatan Overall Equipment Effectiveness. Overall Equipment Effectiveness digunakan untuk mengetahui tingkat produktivitas dari mesin produksi yaitu mesin jahit. Hasil analisis menunjukkan bahwa tingkat downtime menjadi hambatan bagi perusahaan dalam melakukan proses produksi karena menurunnya kecepatan dan performa mesin. Hal ini disebabkan oleh kurangnya perawaatan pada mesin jahit yang digunakan. Hasil perhitungan nilai OEE menunjukkan bahwa mesin jahit sudah mencapai standar persentase world class yang dianjurkan oleh Japan Institure Of Plant Maintenance. Dari perhitungan Six Big Losses ditemukan bahwa kerugian terbesar yang terjadi adalah defect losses. Terdapat tiga penyebab dari terjadinya kerugian, faktor penyebab tersebut meliputi faktor manusia, metode, dan mesin.

References

Alexander, Y., Eko Putra, F. & Anggun Sari, P., 2024, ‘Implementation of Total Productive Maintenance on Frame Welding Machine Maintenance Using the Overall Equipment Effectiveness (OEE) Method at PT Electronics Components Indonesia’, International Journal of Innovative Science and Research Technology (IJISRT), 353–362.

Dwi Cahyono, S., Budiharti, N., Negeri, P., Dinas, S., Kerja, T., Provinsi, D.T. & Timur, J., no date, IMPLEMENTASI TOTAL PRODUCTIVE MAINTENANCE PADA MESIN PRESS DRYER DI PT. TRI TUNGGAL LAKSANA.

febri prabowo, rommy, 2020, Total Productive Maintenance (TPM) pada Perawatan Mesin Grinding Menggunakan Metode Overall Equipment Effectiveness (OEE).

Gianfranco, J., Taufik, M.I., Hariadi, F. & Fauzi, M., 2022a, ‘PENGUKURAN TOTAL PRODUCTIVE MAINTENANCE (TPM) MENGGUNAKAN METODE OVERALL EQUIPMENT EFFECTIVENESS (OEE) PADA MESIN REAKTOR PRODUKSI’, 3(1).

Gianfranco, J., Taufik, M.I., Hariadi, F. & Fauzi, M., 2022b, ‘PENGUKURAN TOTAL PRODUCTIVE MAINTENANCE (TPM) MENGGUNAKAN METODE OVERALL EQUIPMENT EFFECTIVENESS (OEE) PADA MESIN REAKTOR PRODUKSI’, 3(1).

Hallioui, A., Herrou, B., Katina, P.F., Santos, R.S., Egbue, O., Jasiulewicz-Kaczmarek, M., Soares, J.M. & Marques, P.C., 2023, A Review of Sustainable Total Productive Maintenance (STPM), Sustainability (Switzerland), 15(16).

Jaya Teknik Andri, A. & Marikena, N., 2023, ‘Total Productive Maintenance (TPM) Pada Perawatan Mesin Grinding Menggunakan Metode Overall Equipment Effectiveness (OEE) Di PT. Amin Jaya Teknik Total Productive Maintenance (TPM) in Grinding Machine Maintenance Using the Overall Equipment Effectiveness (OEE) Method at PT’, Maret, 1(1).

Kurnia, H., Riandani, A.P. & Aprianto, T., 2023, ‘Application of the Total Productive Maintenance to Increase the Overall Value of Equipment Effectiveness on Ventilator Machines’, Jurnal Optimasi Sistem Industri, 22(1), 52–60.

Muhaemin, G. & Nugraha, A.E., 2022, ‘Penerapan Total Productive Maintenance (TPM) Pada Perawatan Mesin Cutter di PT. XYZ’, Jurnal Ilmiah Wahana Pendidikan, 8(9), 205–219.

Rasyid, M.A. & Sukmono, T., 2024, Seminar Nasional & Call Paper Fakultas Sains dan Teknologi (SENASAINS 7th, vol. 7.

Risonarta, V.Y. & Wardhani, A.K., 2023, ‘INCREASING PROFITABILITY OF A MANUFACTURING COMPANY BY USING THE TOTAL PRODUCTIVE MAINTENANCE APPROACH: A REVIEW’, International Journal of Mechanical Engineering Technologies and Applications, 4(1), 39–50.

Saxena, M.M., 2022, ‘Total productive maintenance (TPM); as a vital function in manufacturing systems’, Journal of Applied Research in Technology & Engineering, 3(1), 19–27.

Seminario-Mestanza, C., Soto-Araujo, A., Collao-Diaz, M., Quiroz-Flores, J.C. & Flores-Perez, A., 2023, ‘Production Model Based on Total Productive Maintenance and Systematic Layout Planning to Increase Productivity in the Metalworking Industry’, Journal of Economics, Business and Management, 11(2), 77–81.

Setiawan, L., 2021, ‘Literature Review of the Implementation of Total Productive Maintenance (TPM) in various Industries in Indonesia’, IJIEM (Indonesian Journal of Industrial Engineering & Management), 2, 16–34.

Singh, S., Agrawal, A., Sharma, D., Saini, V., Kumar, A. & Praveenkumar, S., 2022a, ‘Implementation of Total Productive Maintenance Approach: Improving Overall Equipment Efficiency of a Metal Industry’, Inventions, 7(4).

Singh, S., Agrawal, A., Sharma, D., Saini, V., Kumar, A. & Praveenkumar, S., 2022b, ‘Implementation of Total Productive Maintenance Approach: Improving Overall Equipment Efficiency of a Metal Industry’, Inventions, 7(4).

Sukma, D.I., Prabowo, H.A., Setiawan, I., Kurnia, H. & Fahturizal, I.M., 2022, ‘Implementation of Total Productive Maintenance to Improve Overall Equipment Effectiveness of Linear Accelerator Synergy Platform Cancer Therapy’, International Journal of Engineering, Transactions A: Basics, 35(7), 1246–1256.

Wahid, A., Teknik, J., Fakultas, I. & Pasuruan, T.Y., no date, Penerapan Total Productive Maintenance (TPM) Produksi Dengan Metode Overall Equipment Effectiveness (OEE) Pada Proses Produksi Botol (PT. XY Pandaan-Pasuruan), vol. 6.

Wolska, M., Gorewoda, T., Roszak, M. & Gajda, L., 2023, ‘Implementation and Improvement of the Total Productive Maintenance Concept in an Organization’, Encyclopedia, 3(4), 1537–1564.

Zulkifly, U.K.Z., Zakaria, N. & Mohd-Danuri, M.S., 2021, ‘The adoption of total productive maintenance (Tpm) concept for maintenance procurement of green buildings in Malaysia’, International Journal of Sustainable Construction Engineering and Technology, 12(1), 40–55.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 JURNAL ILMIAH RESEARCH AND DEVELOPMENT STUDENT

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.