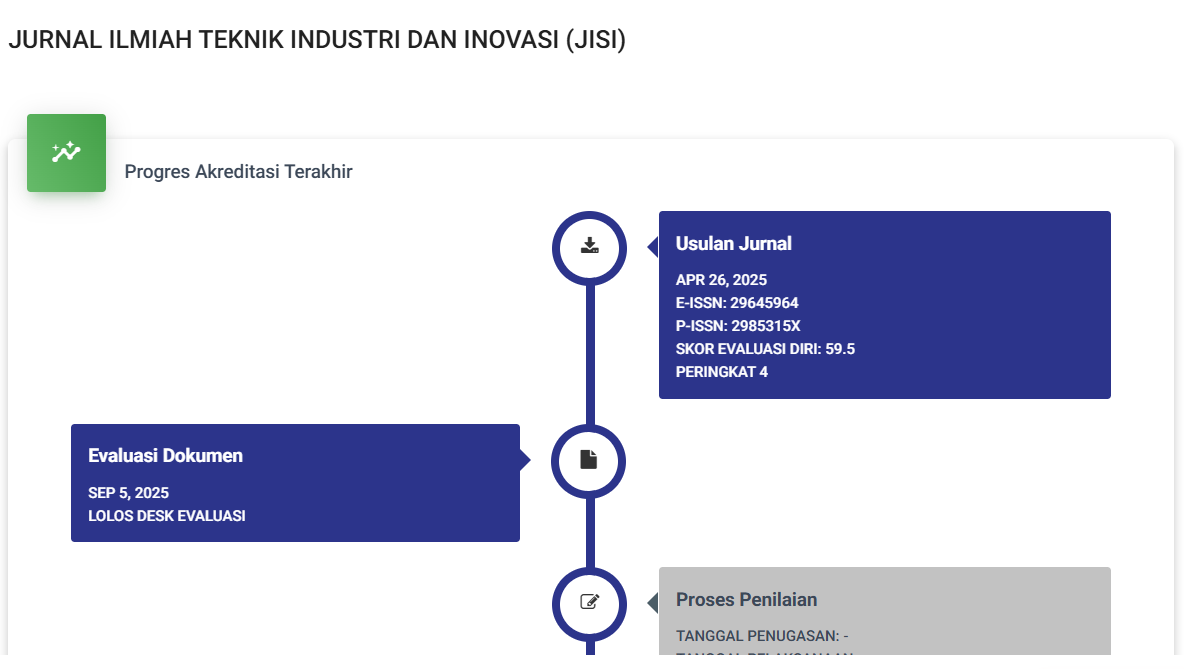

ANALISIS RESIKO KESELAMATAN DAN KESEHATAN KERJA PADA PT RHODA BAKTI JAYA MENGGUNAKAN METODE HAZARD AND OPERABILITY STUDY (HAZOPS)

DOI:

https://doi.org/10.59024/jisi.v3i1.989Keywords:

Likelihood, Consenquences, Matrix Risk, Work Accident.Abstract

PT Rhoda Bakti Jaya is a company located on Jl. Pegangsaan Dua, Blok A1 Km 1.6, Kelapa Gading, Rt 05 / Rw 02 Kec. Kelapa Gading, North Jakarta .PT Rhoda Bakti Jaya is a company engaged in manufacturing PT. Rhoda Bakti Jaya is a company operating in the industrial sector which is located at JL. Pegangsaan Dua, Blok A1 Km 1.6, Kelapa Gading, Rt 05/ Rw 02 Kec. Kelapa Gading, North Jakarta. This company produces various types of components for trucks, namely truck frame or chassis components, brake components and pistons and brake cylinders. This job has a high risk of accidents so that it causes many accidents to workers. Therefore, in this research, using the HAZOP method, we can analyze the level of risk using likelihood, consequences and put it into the risx matrix scale.

References

Ariyani, r., suarantalla, r., & mashabai, i. (2021). Analisa potensi kecelakaan kerja pada pt. Pln (persero) sumbawa menggunakan metode hazard and operability study (hazop). Jurnal industri & teknologi samawa, 2(1), 11–21. Https://doi.org/10.36761/jitsa.v2i1.1019

Bastuti, s., & th, e. (2021). Identification of potential hazards on production machines with hazops and fishbone diagram in pt. Silinder konverter internasional. Sintek jurnal: jurnal ilmiah teknik mesin, 15(1), 17. Https://doi.org/10.24853/sintek.15.1.17-25

Boutadjine, s., korichi, m., & sellami, i. (2023). Hazard and operability study analysis as a semi-automatic approach. Journal of engineering research, 20(1), 52–72. Https://doi.org/10.53540/tjer.vol.20iss1pp52-72

Mindhayani, i. (2020). Analisis risiko keselamatan dan kesehatan kerja dengan metode hazop dan pendekatan ergonomi (studi kasus: ud. Barokah bantul). Simetris: jurnal teknik mesin, elektro dan ilmu komputer, 11(1), 31–38. Https://doi.org/10.24176/simet.v11i1.3544

Nando, r. N., & yuamita, f. (2021). Analisis kesehatan dan keselamatan kerja dengan metode hazard dan operability pada area kerja lantai produksi cv. Lebu berkah jaya. Jie.upy journal of industrial engineering universitas pgri yogyakarta, 1(1), 17–22. Https://journal.upy.ac.id/index.php/jie/article/view/2367

Ratri, m., sabrina, w., & widharto, y. (2016). Analisis potensi bahaya dengan metode hazard and operability study melalui perangkingan risk assessment studi kasus: divisi spinning unit 4 ring yarn pt apac inti corpora. Nalisis potensi bahaya dengan metode hazard and operability study melalui perangkin. Nalisis potensi bahaya dengan metode hazard and operability study melalui perangkingan risk assessment studi kasus: divisi spinning unit 4 ring yarn pt apac inti corpora, 2(1), 1–7.

Rst, r., yulistria, r., handayani, e. P., & nursanty, s. (2021). Pengaruh keselamatan dan kesehatan kerja (k3) terhadap produktivitas kerja karyawan. Swabumi, 9(2), 147–158. Https://doi.org/10.31294/swabumi.v9i2.11015

Trisnayanti, a. P., & iriani, y. (2023). Prisma sains: jurnal pengkajian ilmu dan pembelajaran matematika dan ipa ikip mataram work safety risk analysis using hazard and operability study (hazop) and job safety analysis (jsa) methods in cv. Xyz. Prisma sains, 11(1). Https://doi.org/10.33394/j-

Downloads

Published

Issue

Section

License

Copyright (c) 2024 JURNAL ILMIAH TEKNIK INDUSTRI DAN INOVASI

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.