Analisis Pengendalian Kualitas Produk Dengan Metode Six Sigma dan TRIZ Untuk Mengurangi Jumlah Kecacatan Produk Di UD Cantenan

DOI:

https://doi.org/10.59024/jisi.v2i2.642Keywords:

Keywords: Quality Control, Six Sigma, DMAIC, TRIZAbstract

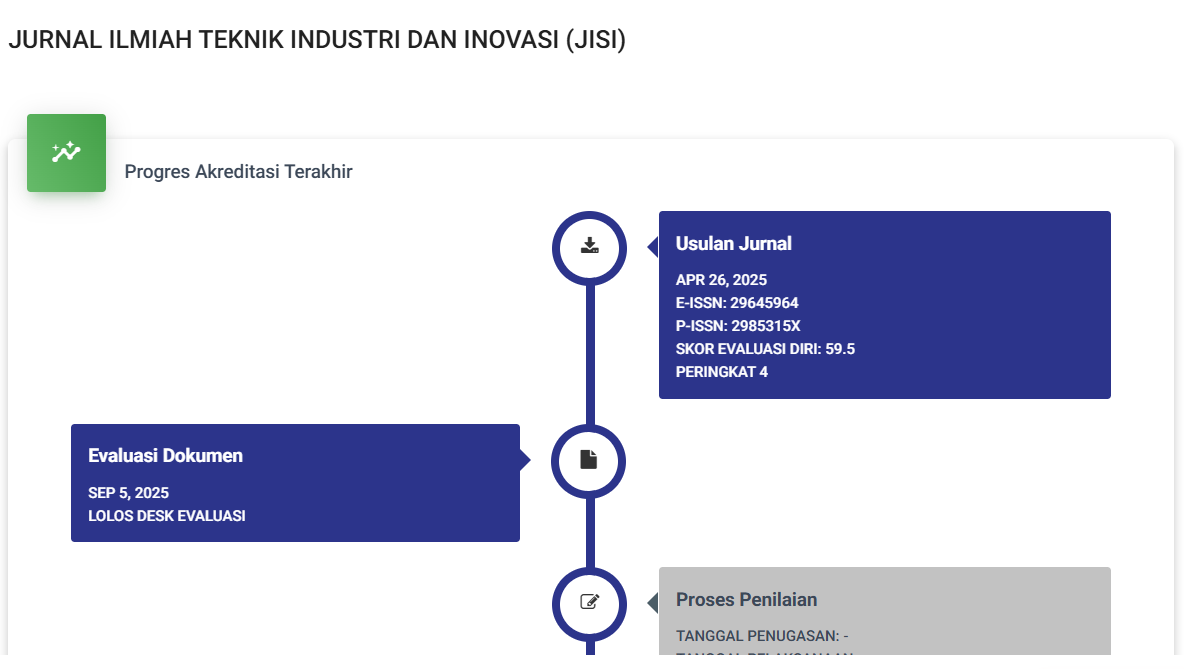

Abstract. UD Cantenan is an industrial company engaged in metal casting, especially made from Aluminum. This company is known to have quality control problems in the manufacture of lip handle products and canal parts. The result of this problem is defective products in the lip handle and canal parts. In this case, of course, the company will spend more to repair the product so that the company experiences losses. Companies need to find ways to reduce the number of defective products. In this study, the Six Sigma method was used with DMAIC (Define, Measure, Analyze, Improve Control) and TRIZ stages to analyze and provide solutions to improve problems that occurred in the company. Based on the research conducted, at the define stage there are 3 types of defects in the lip handle product and canal parts, namely small scratches, small pinholes, and asymmetrical patterns. Then the measure stage obtained the percentage of small scratch defects of 54.47%, small pinholes of 17.3% and asymmetrical patterns of 28.2%. The average DPMO score obtained is 25,720 with a sigma level of 3.45 which shows that UD Cantenan can be categorized as good for industry in Indonesia. Furthermore, at the analysis stage Based on the identification of causal factors using FMEA analysis, it is known that the biggest contributing factor to failure is operator error in the operation of the milling machine. Then at the improve stage, make improvement proposals based on obtaining the highest RPN value from the factors causing disability using the TRIZ method. And the last stage, namely control, is the result of proposed improvements that can be made by the company to solve problems to reduce the number of product defects that occur during the production process.

References

S. Assauri, Manajemen Pemasaran, Jakarta: Rajawali Pres, 2004.

S. Assauri, Manajemen produksi dan operasi, Jakarta: Fakultas Ekonomi, Universitas Indonesia, 2008.

J. P. Costa, I. S. Lopes dan J. P. Brito, Six Sigma Application For Quality Improvement of The Pin Insertion Process, vol. 38, Procedia Manufacturing, 2019.

J. A. Defeo, Juran’s Quality Handbook: The Complete Guide To Performance Excellence (7th ed.), Amerika: McGraw-Hill Education, 2017.

M. Djaelani dan E. Retnowati, “Pengaruh Pengawasan Kerja Dan Penerapan Program Keselamatan Dan Kesehatan Kerja Terhadap Produktivitas Pekerja Proyek Konstruksi,” Jurnal Ilmiah Satyagraha, vol. 5, no. 2, pp. 32-38, 2022.

E. Domb, J. Miller, E. Magran dan M. Slocum, “The 39 Features of Altshuller's Contradiction Matrix,” The TRIZ Journal, pp. 1-4, 2007.

N. Erni, I. S. Kumala dan W. Y. Tri, “ Peningkatan Kualitas,” Jurnal Ilmiah Teknik Industri Pelayanan dengan Metode Servqual dan TRIZ di PT. XYZ, vol. 2, no. 2, pp. 92-100, 2014.

V. Gaspersz, Lean Six Sigma for Manufacturing and Services, Jakarta: PT Gramedia Pustaka Utama, 2007.

V. Gaspersz, Sistem Manajemen Kinerja Terintegrasi Balanced Scorecard Dengan Six Sigma Untuk Organisasi Bisnis dan Pemeritah, Jakarta: PT Gramedia Pustaka Utama, 2005.

P. Gupta, Six Sigma bussiness scorecard: Ensuring performance for profit, McGraw-Hill Education, 2004.

A. R. Heryadi dan W. Sutopo, “Review Pemanfaatan Metodologi DMAIC Analysis Di Industri Garmen,” Seminar dan Konferensi Nasional IDEC, 2018.

S. Kumar dan d. , “Six Sigma an Excellent Tool for Process Improvement – A Case Study,” International Journal of Scientific & Engineering Research, vol. 2, no. 9, 2011.

S. Prawirosentono, Manajemen Operasi (Operations Management) Analisis dan Studi Kasus, Edisi 4 penyunt., Jakarta: Penerbit Bumi Aksara, 2007.

R. S. Russel dan B. W. Taylor, Production and Operations Management: Focusing on Quality and Competitiveness, New Jersey: Prentice Hall. Inc., 1996.

P. N. Serarawani, “Pengembangan Perancangan Alat Mixing Sabun Cair Yang Sesuai Kaidah Ergonomi,” Jurnal Valtech (Jurnal Mahasiswa Teknik Industri), vol. 3, no. 1, pp. 77-82, 2020.

H. Sirine dan E. P. Kurniawati, “Pengendalian Kualitas Menggunakan Metode Six Sigma (Studi Kasus Pada PT Diras Concept Sukoharjo),” AJIE-Asian Journal of Innovation and Entrepreneurship, vol. 2, p. 256, 2017.

C. Spreafico dan D. Russo, “TRIZ industrial case studies: a critical survey,” I15th TRIZ Future Conference, vol. 39, pp. 51-56, 2016.

K. T. Ulrich dan D. E. S, Perancangan & Pengembangan Produk, Jakarta: Salemba Teknika, 2001.

A. T. Wahyuningtyas, M. Mustafid dan A. Prahutama, “Implementasi Metode Six Sigma Menggunakan Grafik Pengendali EWMA Sebagai Upaya Meminimalisasi Cacat Produk Kain Grei,” Jurnal Gaussian, vol. 5, pp. 61-70, 2016.

L. Webber dan M. Wallace, Quality Control For Dummies, Indiana: Wiley, 2007.

P. Wisnubroto dan A. Rukmana, “Pengendalian Kualitas Produk Dengan Pendekatan Six Sigma Dan Analisis Kaizen Serta New Seven Tools Sebagai Usaha Pengurangan Kecacatan Produk,” Jurnal Teknologi, vol. 8, no. 1, pp. 65-74, 2015.

E. P. Wulandari, M. Y. Lubis dan A. A. Yanuar, “Usulan Perbaikan Untuk Meminimasi Defect Short Mold Pada Proses Peleburan Produk Grip Panjang Di CV. Gradient Dengan Menggunakan Pendekatan Six Sigma,” e- Proceedings of Engineering, vol. 5, pp. 3031-3038, 2018.

J. Zhang, K. H. Chai dan K. C. Tan, “40 Inventive Principles with Application in Service,” Metodolog.Ru, pp. 1-8, 2015.

W. Zulkarnaen, A. Suarsa dan R. Kusmana, “Pengaruh Pelatihan Kerja Dan Stres Kerja Terhadap Produktivitas Kerja Karyawan Bagian Produksi Departemen R-Pet Pt. Namasindo Plas Bandung Barat,” Jurnal Ilmiah Manajemen, Ekonomi, & kuntansi (MEA), vol. 2, no. 3, pp. 151-177, 2018.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Ndoro Jatun Kuncoro Jakti, Ari Zaqi Al Faritsy

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.